May 20th, 2021 | 5 min read

3PL, also known as third-party logistics, fulfillment services provider, fulfillment house, fulfillment company, shipping logistics, shipping logistic services, logistic services, outsourced warehouse, FBA (fulfillment by Amazon) alternative, warehousing, is an organization’s use of third-party businesses to outsource elements of its distribution, warehousing, and fulfillment service.

As a company expands to sell more products and serve new markets, many business owners and operations managers have asked: Should I outsource warehousing and shipping? Today, more than ever before, professionals have turned to 3PLs (third-party logistics) to handle just that.

By outsourcing shipping and fulfillment operations, business owners and operations managers alike have been able to cut costs, reduce risk, and put their time back to where it matters most: growing their business.

If you’re interested in learning about the ins and outs of 3PLs – from the benefits to automation and integration – keep reading our complete guide.

One of the main reasons why businesses choose to use a 3PL is the long and short-term savings. You do not have to deal with warehouse space, warehouse employees, transportation, or additional tech. From an employee standpoint, 3PLs eliminate paperwork, audits, insurance, worker’s comp, and employee training. Similarly, you do not have to personally invest in warehouse software, robots, converter belts, or security systems. Overall, 3PLs keep fixed costs to a minimum. Most fees are marginal or monthly.

Using a 3PL is far more suitable in the long term than attempting to do everything in-house. Having warehouses in different locations allows you to increase or decrease your inventory as you see fit while selling a wider variety of products without financial risk. Having inventory spread across various locations lowers shipping costs and shipping times. Click here to learn more about the benefits of distributed warehousing.

Importantly, leveraging 3PLs allows you to allocate your time and effort strategically. You are not a logistics expert; you receive their expertise.

Now, you’re probably wondering: How much will it cost your business?

A one-time setup fee typically can be $1000 or more. From there, there are other associated costs for shipping, receiving, and packaging. Regarding shipping and receiving, an hourly rate is charged based on the number of employees needed to help unload and store your products. This rate can range from $25-$50 per hour. Depending on size and customization, 3PLs typically charge $0.25 to $2 per package.

Alternatively, some 3PLs charge a flat rate based on various factors, for example, per item, square foot, order, or pallet. Ensure you do your research and have conversations with warehouses to get an understanding of their associated costs.

There are various reasons why a business may choose to start looking for a 3PL. Here are some of the most common:

Growing businesses tend to bring rising logistics costs and infrastructure restraints. Inevitably, as your customer service capacities decrease, these additional costs and burdens will lead to customer dissatisfaction.

Another reason many business owners opt for 3PLs is to focus on their business’s growth. For example, they seek to expand into a new region and cannot commit to a new facility. Alternatively, increased training or investments in skilled labor is sometimes impossible, so businesses must consider other avenues to foster growth.

Unsurprisingly, warehouses have high associated insurance, shrinkage, and employee liability costs. When businesses opt to use a 3PL, they reduce their upfront costs and overall risk.

The underlying question, however, is: at what point does it become cost-effective to use a 3PL? Of course, this varies from business to business. Still, if all of your costs (monetary and otherwise) exceed those associated with a 3PL, it may be a strategic solution to consider.

Duoplane can automate sending POs, inventory syncing, & shipment feeds. Get in touch with us to start your free trial!

To reap all of the benefits of outsourcing to a 3PL, it is essential that your company prioritizes transparent communication with the provider and keeps track of the operation. Equally, your business and the 3PL must have a mutual understanding of each other’s business.

Communication is essential for any third-party contract. From the beginning, ensure that you have a properly written RFP (request for proposal) complete with baseline and benchmark costs. Compiling and communicating accurate information is essential to creating a mutually beneficial partnership.

Similarly, communicating your expectations, goals, and KPIs with your 3PL is crucial to ensuring you are a good match. KPIs include on-time percentages, maximum return rates, and inbound receiving time. Including these evaluation metrics in your service level agreements can incentivize partners to strive for maximum performance. Equally, should these standards be met (or exceeded), your customer satisfaction rate will thrive.

Finding a balance between a hands-off and a micromanagement approach can prove challenging. While you have entrusted a third party, regular oversight of business operations is still essential for efficiency and profitability.

Establishing a regular reporting schedule ensures all parties are on track to success and any kinks get worked out as soon as possible. For instance, should a KPI drop or a return slip through the cracks, troubleshooting a plan via regular check-ins can prevent or remedy minor issues before they culminate.

Designate a single point of contact to check in with an account or production manager to avoid redundancy and establish a solid working relationship. This person will complete regular check-ins and inform the 3PL of company changes.

Ideally, a mutual understanding of one another’s strengths and weaknesses, goals, and nitches should come from transparent communication with your 3PL. These discussions about differentiators or competitive markets should foster better collaboration and a strengthened partnership fit to serve a mutual customer.

We’ve been the industry-leading solution to automate dropshipping operations for over 12 years. Check out our reviews page to learn why our clients love us.

Decades ago, companies could manually complete transfer information and keep 3PLs informed via email. Today, however, business and customer expectations have changed. With industry leaders like Amazon fulfilling orders overnight, customers have new demands from other retailers—for example, a seamless purchasing experience and real-time tracking information.

In short, fully automating your 3PL management processes to be more aligned with real-time data is essential for success. In fact, 98% of 3PLs said that developing the quickest means to communicate the most up-to-date information with their customers has become even more essential since 2018.

With that said, let’s dive into which parts of the 3PL process can be automated. Order fulfillment and product updates can be fully automated with the right automation software. This includes inbound shipment requests, purchase orders, and customer orders.

Similarly, 3PL integration software can sync your return merchandise authorization (RMA) with your 3PLs and align your ERP with the warehouses between your business and your 3PLs.

If you’re interested in learning more about how the right automation software can help you streamline your 3PL management, check out our article all about automating your e-commerce storefront.

Integrating various systems and applications is essential to automate your 3PL management and business processes fully. Some areas that should be in sync with your 3PLs include:

There are 4 major flows to integrate:

Automation and integration are essential to maximizing your 3PL partnerships, as they ensure the utmost efficiency, profitability, and satisfaction. Orders and returns don’t fall through the cracks, manual data transfers are not left until the 11th hour, and catalogs are always up-to-date.

This post was last updated on Aug 24, 2023.

Absolutely! Third-party logistics (3PL) providers are indispensable assets to modern supply chains. Here are some reasons why:

Utilizing third-party logistics (3PL) providers, while beneficial in many respects, can present several challenges:

The move towards leveraging 3PL services is due to the myriad benefits they offer for scaling businesses. Here are some key benefits and reasons why:

Third-party logistics (3PL) warehouses play an integral role in enhancing customer satisfaction in various ways:

Yes, you can integrate 3PL services with Shopify. Shopify is designed to work seamlessly with many third-party logistics providers. This integration streamlines storage, order fulfillment, and shipping processes. However, it’s crucial for store owners to confirm integration capabilities with their chosen 3PL. While many offer seamless integration, not all might have tools or plugins for direct Shopify synchronization.

Duoplane is a dropshipping automation software built by dropshippers, for dropshippers. We’re here to help you streamline your ecommerce retail fulfillment operations and automate order routing, inventory syncing, shipment feeds, and more.

Don’t just take our word for it – check out our reviews and case studies to learn why we’ve been the industry-leading solution for over 12 years, assisting over 300 retailers in onboarding over 2000 vendors and 3PL warehouses.

Experience the best dropshipping automation software risk-free with our 14-day free trial. Our dedicated onboarding specialists will guide you through the setup process, ensuring you’re ready to hit the ground running.

IF YOU DROP SHIP,

THEN YOU’LL LOVE DUOPLANE.

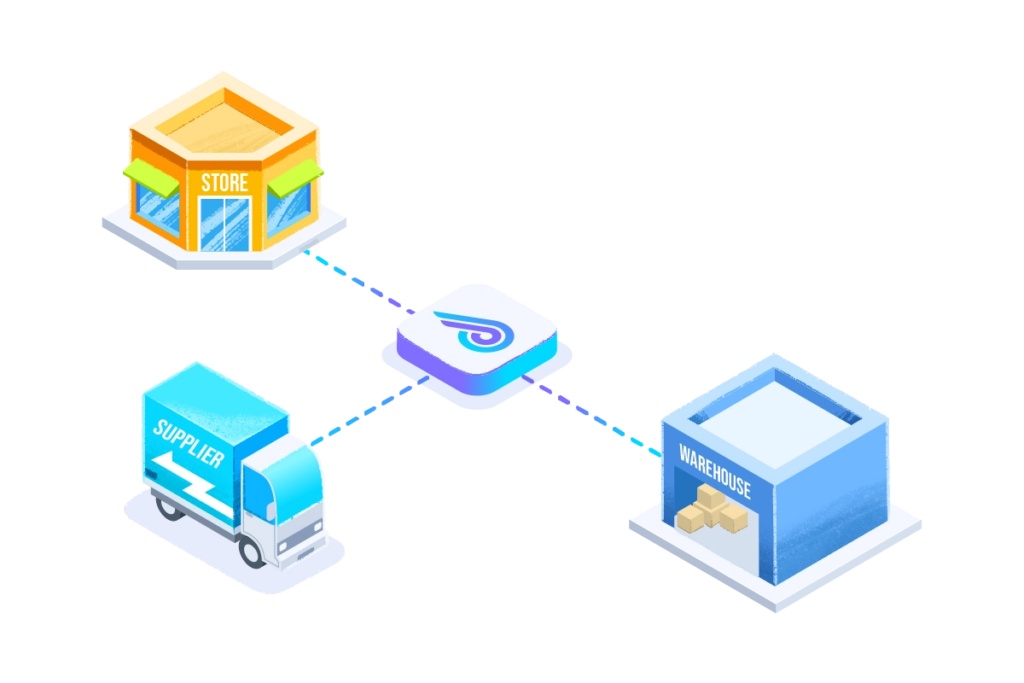

Duoplane intelligently and automatically routes orders to the right vendor or warehouse.

Keep everyone on the same page and save time by allowing vendors to manage their orders.

Automate vendor inventory feeds to keep your product catalog accurate.

Stay on top of your books by connecting with your accounting system to sync vendor invoices.

Streamline your operations and centralize orders from all of your e-commerce channels

Manage the full order cycle, including changes, shipments, returns, and order exceptions.

Duoplane connects to your existing systems to minimize manual effort by you or your team.

Provide feedback to vendors using actionable performance metrics.

Curious what Duoplane can do? See for yourself with a free trial.

Get in touch with us today!